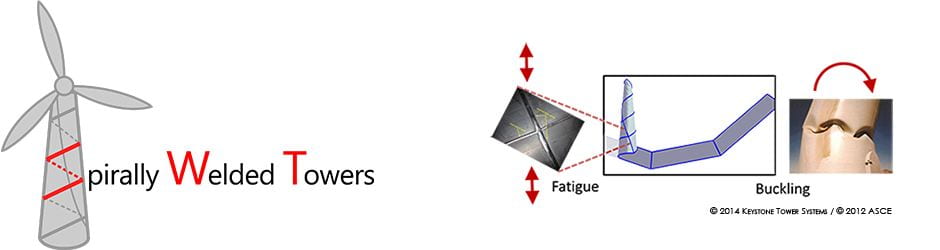

Spirally Welded Towers

Renewable energy is critical to the long-term sustainability of the nation. In particular, wind energy, a vast domestic resource, has the potential to totally transform the energy economy of the U.S. The U.S. Department of Energy (DOE) lists the development of renewable energy sources as an immediate national need, and has set a target for the U.S. to generate 20% of its electricity from wind energy by 2030. As of 2013, the United States generates ~3% of its electricity from wind energy, and it is clear that transformative advances in wind generated energy technology are vital to obtain the ambitious vision of the DOE. Specifically, wind turbine towers must be manufactured taller and cheaper. Keystone Tower Systems has developed an innovative manufacturing technology, based on automated spiral welding that enables conical, slender towers to be produced on-site in a highly efficient fashion. The benefits to this are two-fold: first, the automation reduces production costs dramatically compared to traditional practices and, second, the on-site fabrication precludes transport limits that currently inhibit both tower height and the structurally optimal distribution of material. An important barrier to the deployment of this technology is a lack of fundamental understanding of the limit states for this particular structure and, generally, for slender shells.

To overcome this barrier, Northeastern University and Johns Hopkins University are executing a program of fundamental analytical and large-scale experimental research into the limit states of and design standards for slender towers with particular emphasis on those manufactured with spiral welding. Existing design methods for slender towers and shells are unsatisfactory, relying on overly conservative, empirically derived knockdown factors, not having a firm probabilistic basis, and never having been applied to spiral welded pipe loaded in flexure. We aim to probabilistically characterize the controlling limit states of slender tubes and, based on this characterization, develop a rigorous reliability-based design approach. Directly coupled with this academic effort, Keystone Tower Systems is developing and prototyping its manufacturing process and imperfection assessment procedures with explicit consideration of the cost-benefit tradeoff between manufacturing tolerances and structural performance.

This project is supported by the National Science Foundation, the Massachusetts Clean Energy Center and the Department of Energy.

.